Release date:2024-10-18 16:35 Browse times:

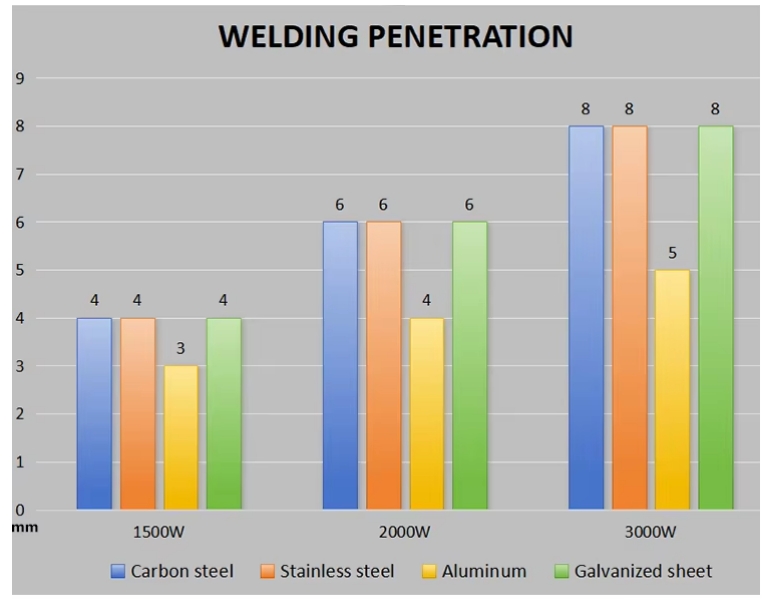

The welding thickness that can be achieved with a handheld metal laser welding machinedepends on several factors, including the power output of the laser, the material being welded,the speed of welding, and the focus of the laser beam, Here are some general guidelines for thewelding thickness capabilities of 1500W, 2000w, and 3000w handheld metal laser welding machines:

o Typically, this power level is suitable for welding thin to medium-thickness materials.

o Commonly used for welding stainless steel up to about 3mm (0.118 inches) thick.

o For aluminum, the thickness might be slightly less due to its higher reflectivity and

thermal conductivity.

o Offers greater penetration depth and can handle thicker materials more effectively.

o Can weld stainless steel up to about 5mm (0.197 inches) thick.

o Aluminum welding capability might extend to around 3mm (0.118 inches).

o Provides even deeper penetration and is capable of welding thicker materials.

o Can weld stainless steel up to about 8mm (0.315 inches) thick or more, depending onthe specific application and setup.

o For aluminum, it can typically handle thicknesses up to about 6mm (0.236 inches) or more.

If you have any questions, add my friends

Skype:hellomike00