portable laser welder cutting cleaning 4 in 1 laser welding machines for steel metal stainless aluminum

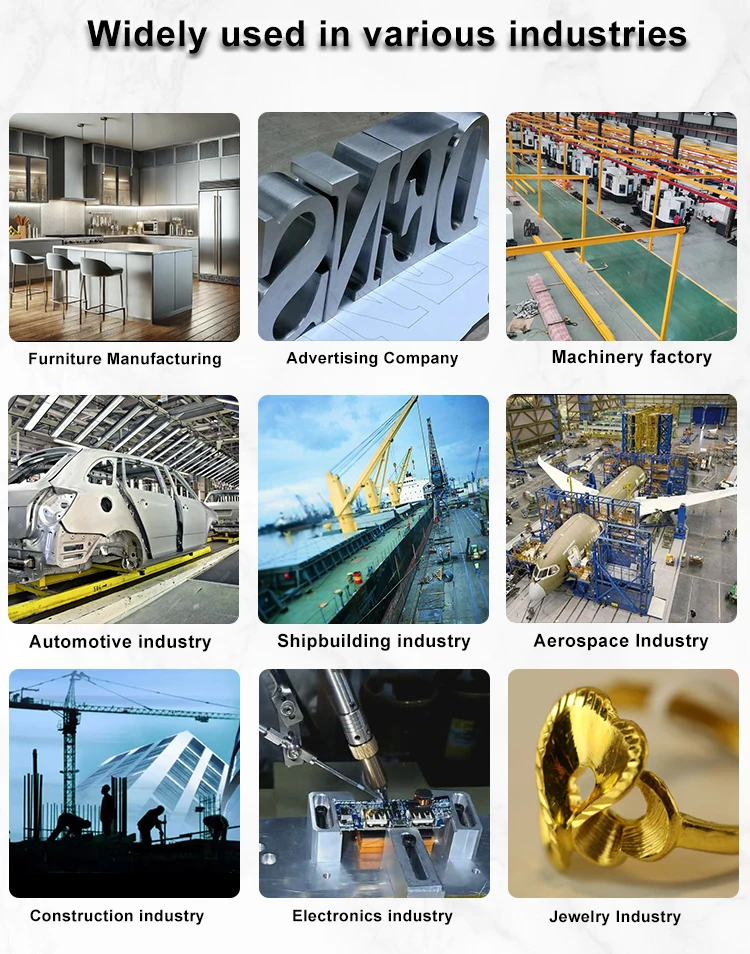

Handheld Fiber Laser welding can be used in welding stainless steel, aluminum, copper, gold, silver, chromium, nickel, titanium and other metals or alloys, can also be used for a variety of welding between different materials, such as: copper – brass,titanium –gold, Titanium – molybdenum, nickel – copper and so on. Welding range: 0.5~8mm carbon steel,0.5~4mm stainless steel,aluminium alloy 0.5~6mm, brass 0.5~4mm.

Main Feature of hand held laser welding machine

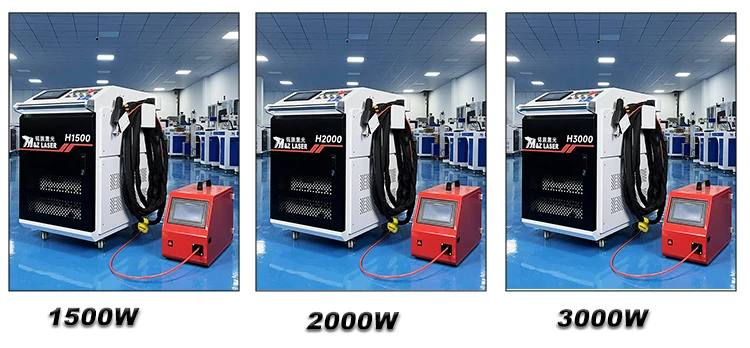

1.The system is mainly composed of a laser source, a welding system and water chiller.

2. Hand-held welding, taking into account the flexibility, high efficiency and high weld quality of laser welding.

3. Modular design and layout of the overall equipment, beautiful and easy to maintain and debug.

4. High system flexibility, compatible with a variety of models, and short changeover time.

5. The internal design is dexterous, and the good interactive control system expands the tolerance range of the machined parts and the weld width, solves the disadvantage of small spot size, and welds are better formed.

6. The shape is light, the body engineering design method is adopted, and the grip is comfortable; the hand is easy to control, and the operation is simple and easy to use.

7. With multiple safety alarms, the light is automatically locked after the workpiece is removed, and the safety is high.

8. Beautiful weld seam, fast speed, no consumables, no weld marks, no discoloration, no need for post-grinding.

9. Can be equipped with a variety of angle nozzles to meet the welding needs of different products.

Why need automatic wire feeding device?

In actual welding, sometimes part fluctuations and fixture errors often cause various welding defects. After adding wire feed for welding, the laser beam is easy to guide and focus, which can realize welding of any complicated shape, with high degree of automation, fast welding speed, high production efficiency, and stable and reliable processing quality.

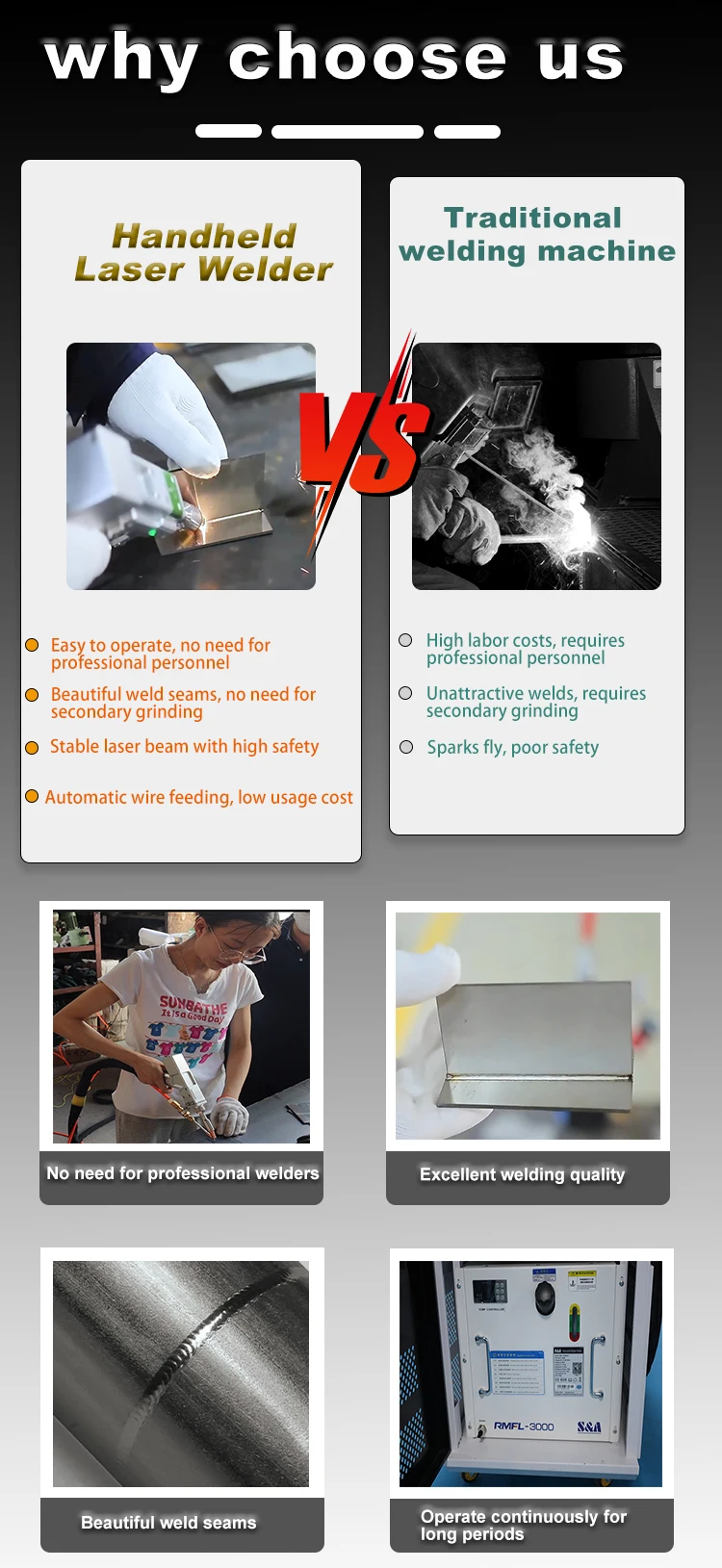

Easy to use, saving labor costs

Compared with traditional arc welding, Handheld fiber laser welding machine enjoys following

advantage: user-friendly design and technology upgrade, simple operation, operators do not need skilled technical certificate to achieve exquisite welding.There is no need for secondary grinding after welding, which greatly reduces the professional limitations of the operator and the cost of manpower.

more than 2 times that of solid YAG laser welding, and 3-5 times that of arc welding. The efficiency of photoelectric conversion is more than 30%, compared to 3% of solid YAG lasers, and low energy consumption reduces more unnecessary costs for production and processing.