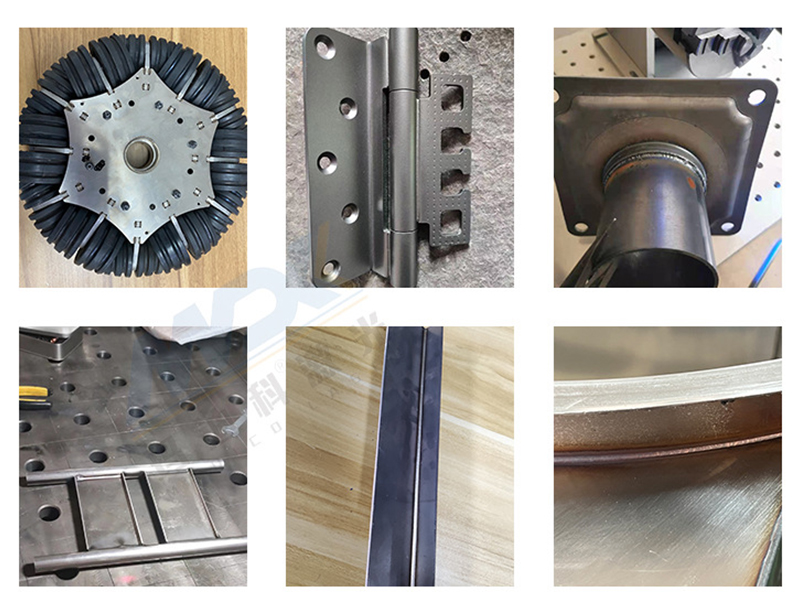

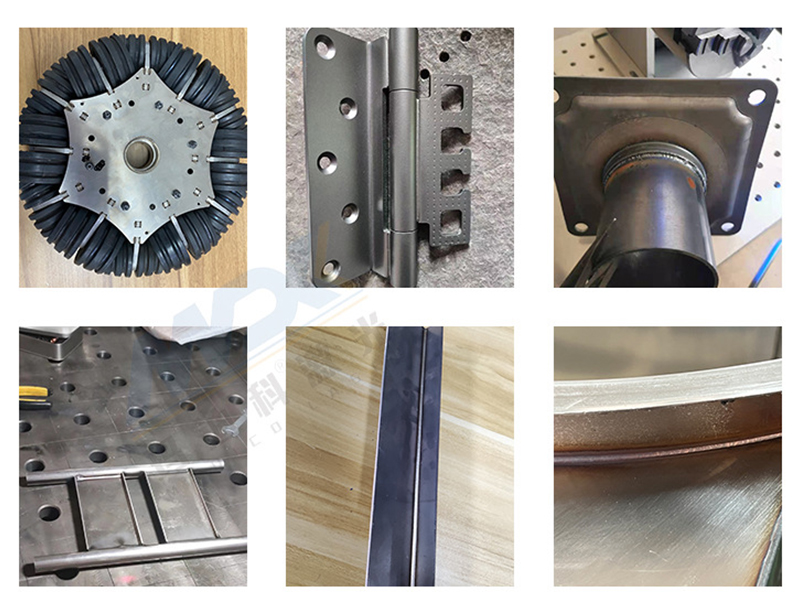

For metals welding, now our handheld fiber laser welding machine is very hot sale, it is easy to use and high welding efficiency and now fiber laser welder machine price is getting cheaper, so many customers will think using hand held fiber laser welding machine to replace their traditional welder.Handheld Fiber Laser welding can be used in welding stainless steel, aluminum, copper, gold, silver, chromium, nickel, titanium and other metals or alloys, can also be used for a variety of welding between different materials, such as: copper – brass, titanium –gold, Titanium – molybdenum, nickel – copper and so on. Welding range: 0.5~8mm carbon steel,0.5~4mm stainless steel, aluminium alloy 0.5~6mm, brass 0.5~4mm....

Product Descriptions

HANDHELD FIBER LASER WELDING MACHINE 1500W WITH AUTO WIRE FEEDER

Handheld Fiber Laser welding can be used in welding stainless steel, aluminum, copper, gold, silver, chromium, nickel, titanium and other metals or alloys, can also be used for a variety of welding between different materials, such as: copper – brass, titanium –gold, Titanium – molybdenum, nickel – copper and so on.

Welding range: 0.5~8mm carbon steel,0.5~4mm stainless steel, aluminium alloy 0.5~6mm, brass 0.5~4mm.

Main Feature of Handheld fiber laser welder machine

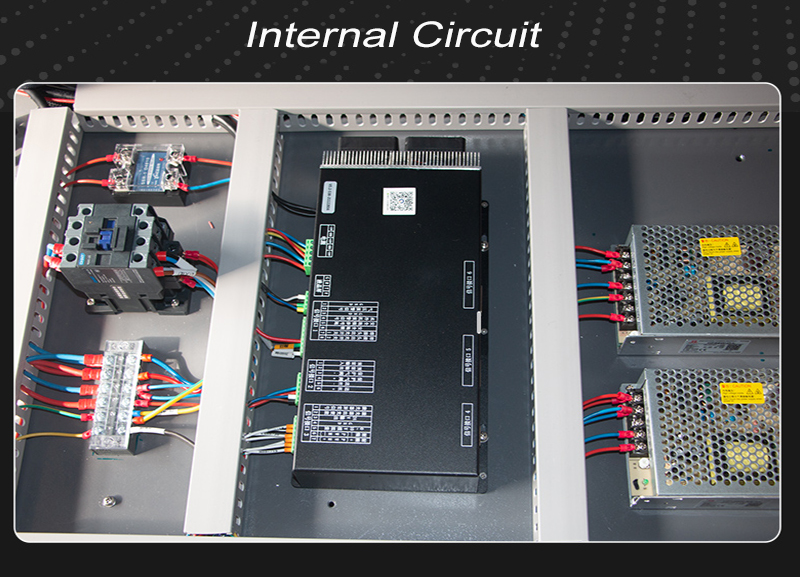

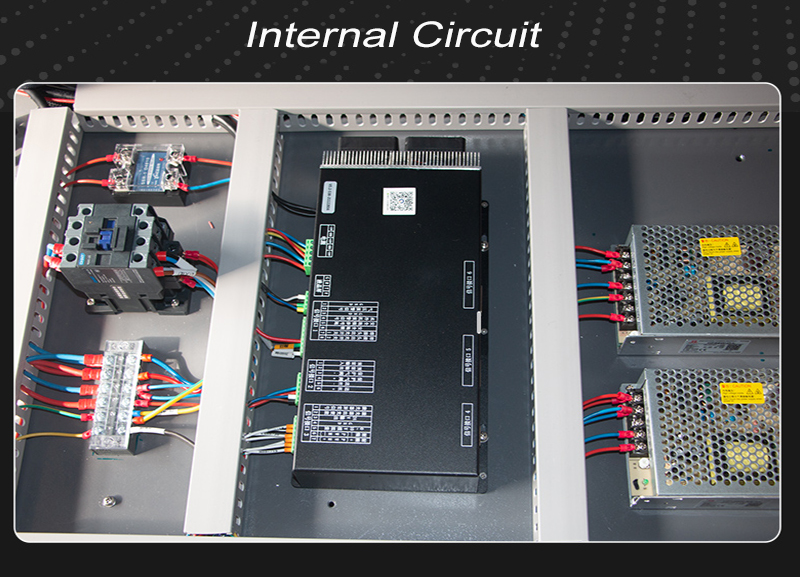

The system is mainly composed of a lasersource, a weldingsystem and water chiller.

2. Hand-held welding, taking into account the flexibility, high efficiency and high weld quality of laser welding.

3. Modular design and layout of the overall equipment, beautiful and easy to maintain and debug.

4. High system flexibility, compatible with a variety of models, and short changeover time.

5. The internal design is dexterous, and the good interactive control system expands the tolerance range of the machined parts and the weld width, solves the disadvantage of small spot size, and welds are better formed.

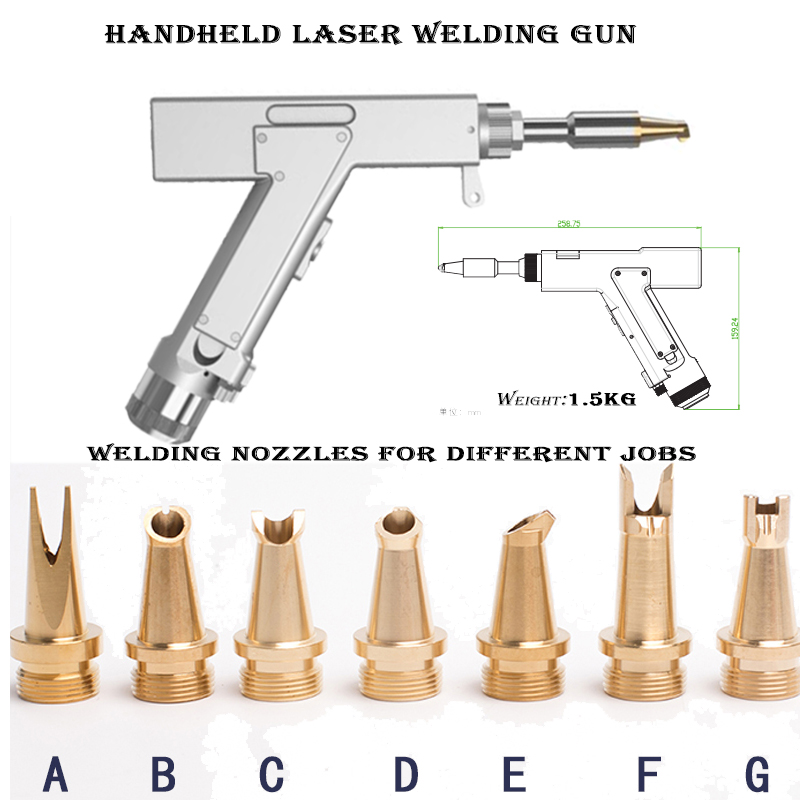

6. The shape is light, the body engineering design method is adopted, and the grip is comfortable; the hand is easy to control, and the operation is simple and easy to use.

7. With multiple safety alarms, the light is automatically locked after the workpiece is removed, and the safety is high.

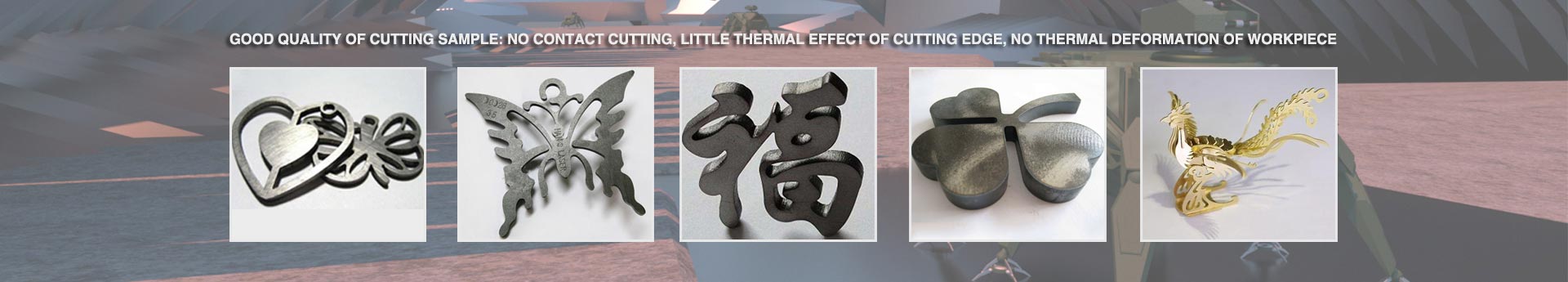

8. Beautiful weld seam, fast speed, no consumables, no weld marks, no discoloration, no need for post-grinding.

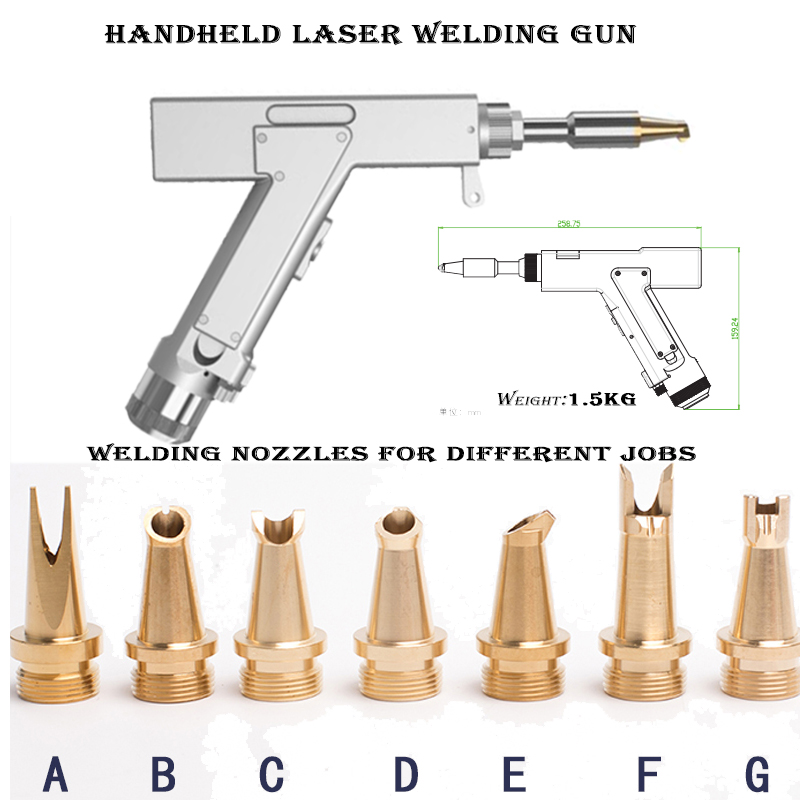

9. Can be equipped with a variety of angle nozzles to meet the welding needs of different products.

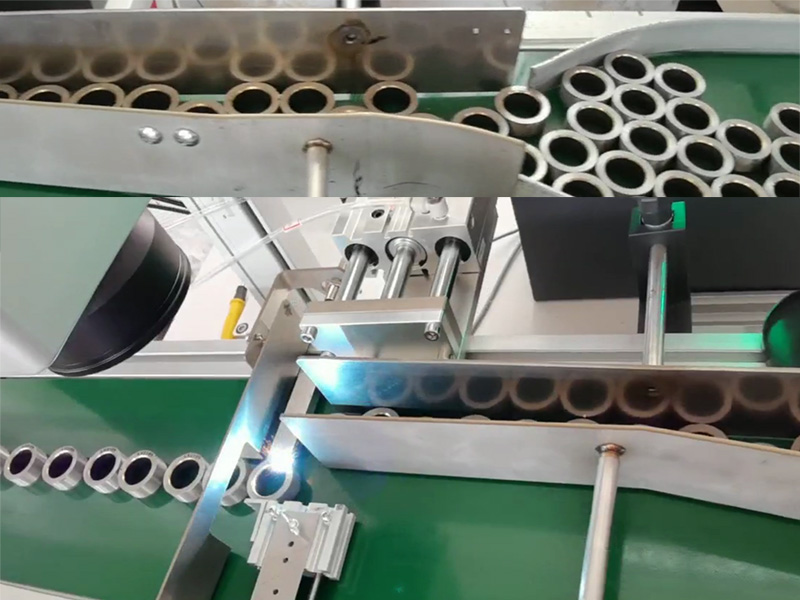

Why need automatic wire feeding?

In actual welding, sometimes part fluctuations and fixture errors often cause various welding defects. After adding wire feed for welding, the laser beam is easy to guide and focus, which can realize welding of any complicated shape, with high degree of automation, fast welding speed, high production efficiency, and stable and reliable processing quality.

Laser welding machine specifications

|

Model

|

1000W 1500W 2000W hand held fiber laser welding machine

|

|

Laser device

|

1000W/ 1500W / 2000W

|

|

Laser wave length

|

1080nm

|

|

Welding speed range

|

0-120mm/s

|

|

Welding gap

|

≤1/5 of the thickness of sheet metal

|

|

Fiber length

|

Standard 12m

|

|

Water cooling

|

HanLil for handheld welding machine 1500W

|

|

Electromechanical

|

380V/50HZ or 220V optional

|

|

Consumable

|

Nitrogen welding, output pressure 0.2Mpa

|

|

Total power

|

6KW

|

|

Dimensions

|

1300X650X1100mm

|

|

Total weight

|

150KG

|

Hand held fiber laser welding machine details