Handheld laser welding machine can be widely used in kitchen cabinets, stair elevators, shelves, ovens, stainless steel door and window guardrail, distribution box, stainless steel household and other industries

It has the advantages of simple operation, beautiful weld, fast welding speed and no consumables.Welding of metallic materials such as thin stainless steel, carbon steel and galvanized sheet is a perfect alternative to conventional tiG and electric welding....

Product Descriptions

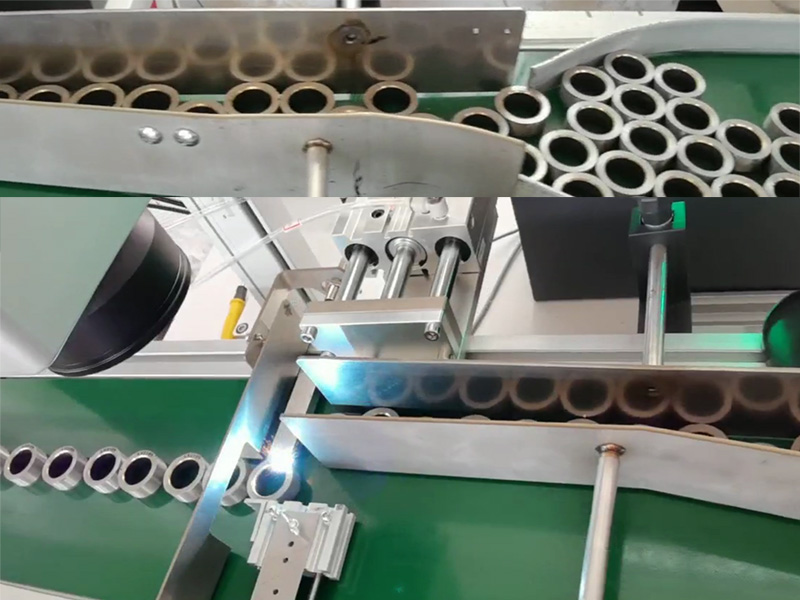

The handheld optical fiber laser welding machine of mzlaser. changes the traditional welding mode, adopts the high-intensity laser beam as the heat source for welding, and is equipped with a hand-held dither welding gun instead of the previous fixed optical path.

It has the advantages of simple operation, beautiful weld, fast welding speed and no consumables.

Welding of metallic materials such as thin stainless steel, carbon steel and galvanized sheet is a perfect alternative to conventional tiG and electric welding.

Handheld laser welding machine can be widely used in kitchen cabinets, stair elevators, shelves, ovens, stainless steel door and window guardrail, distribution box, stainless steel household and other industries

Portable handheld fiber laser welding machine is a perfect replacement of traditional argon arc welding machine in welding thin stainless steel plate, iron plate, aluminum plate and other metal materials.. It performs faster welding speed, its working efficiency is nearly 10 times of traditional argon arc welding. Very very easy to use. Just taking around 3 hours training, the common workers will be able to operate it smoothly, no need traditional welding experience. For laser welding machine, its welding effect is clean and nice, no need to polishing and more second processing. It can save more your labor cost. Small heat affected zone to ensure smaller welding formation of welding materials. It can weld the sheet thickness less than 1mm easily, while it’s nearly impossible or difficult for argon arc welding machine to achieve good quality welding effect.

Application

1. Its welding head could be widely used in complex and irregular welding process such as cabinets, kitchen, staircase, shelf, gridiron, stainless steel door and window guardrail, distribution box, stainless steel furniture and other industries. It's a perfect replacement of traditional argon arc welding, in welding thin stainless steel plate, iron plate, aluminum plate and other metal materials.

2. Smart internal design and interactive control system expan the tolerance range and welding width of the processing parts, and solve the disadvantage of minor laser welding spot, and provide better welding forming.

3. Light shape, Ergonomic design, advanced structure, and reliable performance ensure comfort grip and simple operation.

4. With multiple safety alarms, it auto locks light after removing the work piece, which is safe.

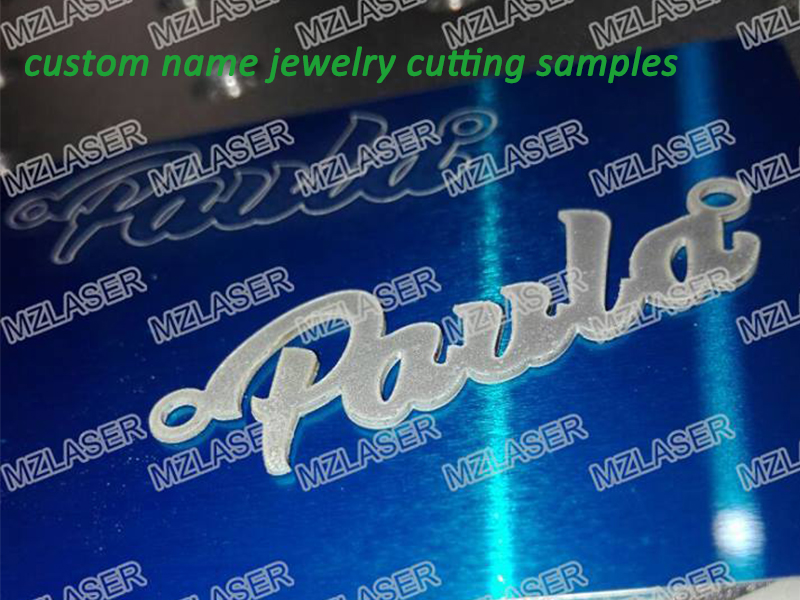

5. Nice welding seam, fast welding speed, no consumables, no welding marks, no discoloration, no later polish.

6. This head could be equipped with a variety of angular nozzles to meet the welding needs of different products.

Mainl Applied Materials:

This portable handheld fiber laser welding machine is mainly applied to the metal sheet within 3mm thickness.

l Such as: All thin stainless steel sheet ( model:304,316,201 )

l Carbon steel, alloy steel sheet ( 20#,45#,Q235,Q345 )

l Alumimum sheet ( Thickness had better be within 1.5mm)

-

Handheld Fiber laser soldering machine display

Technical parameters:

1) Type of interface: QBH

8) Total weight: 1.36kg

|

NAME

|

Portable Handheld Fiber Laser Welding Machine

|

|

Machine Model

|

MZ-LW1000H

|

MZ-LW1500H

|

|

Laser Power

|

1000 watts

|

1500 watts

|

|

Input Voltage

|

220V 50HZ

|

|

Laser Type

|

Fiber Laser Source

|

|

Laser wavelength

|

1070+20 nm

|

|

Type of interface

|

QBH

|

|

Laser incidence mode

|

Coaxial

|

|

Collimating focal length

|

50mm

|

|

Linewidth Adjustable Amplitude

|

0-4mm

|

|

Focus length

|

80mm 120mm

|

|

Welding speed

|

0-120mm/s

|

|

Fiber length

|

Standard:10M, Max:15M

|

|

Metal sheet thickness

|

0.5-3mm

|

|

Welding head weight

|

1.5kg

|

|

Output Laser Power Regulation Range

|

10-100%

|

|

Working Environment Temperature Range

|

15-35℃

|

|

Welding Thickness

|

0.5-3mm

|

|

Welding Gap Requirements

|

≤0.5mm

|