This welder is specially developed for laser welding of jewelry by MZLASER and mainly used in perforating and spot welding of gold and silver jewelry. The laser spot welding is an important aspect of laser process technology application.The spot welding process is thermal conduction, The laser radiation heats the surface of work piece,and the surface heat diffuse to the interior through thermal conduction and melts the work piece by controlling the width, energy, peak power and repeating frequency of laser- pulse to form specific molten pool. Because of its unique advantage,it is widely used in the process of gold and silver jewelry and welding of mini and small parts....

Product Descriptions

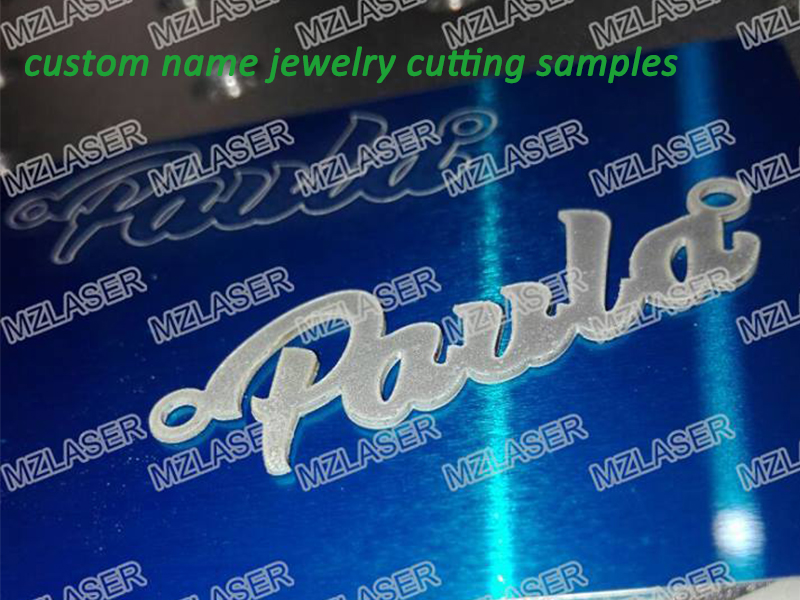

Gold Silver Mini Laser Welding Machine for Jewelry Soldering

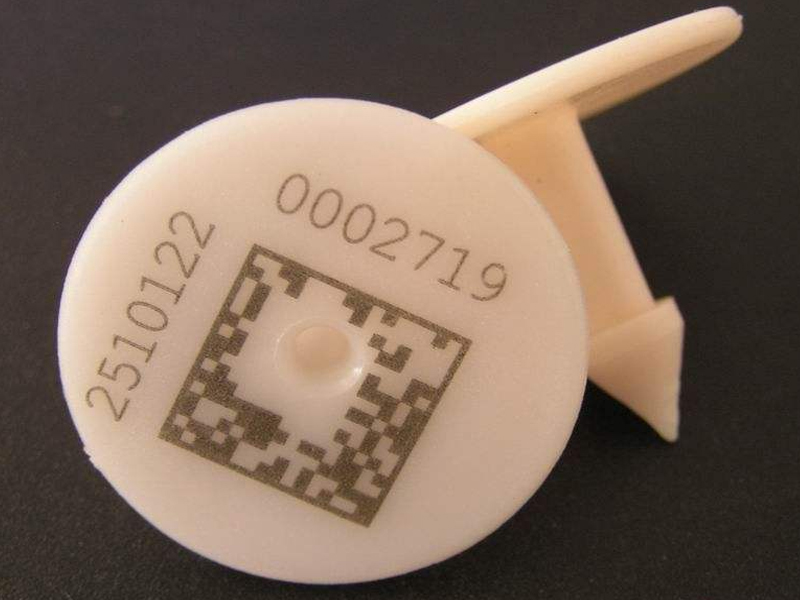

Application of Laser welding machine

Jewelry laser spot welding machine is widely used in aviation, aerospace, sporting goods, jewelry, golf clubs, medical equipment, aluminum alloy dentures, instrumentation, electronics, machining, automotive and other industries, in particular for the hole of gold and silver jewelry, Spot welding seams, inlaid force pieces and claw foot parts and other welding

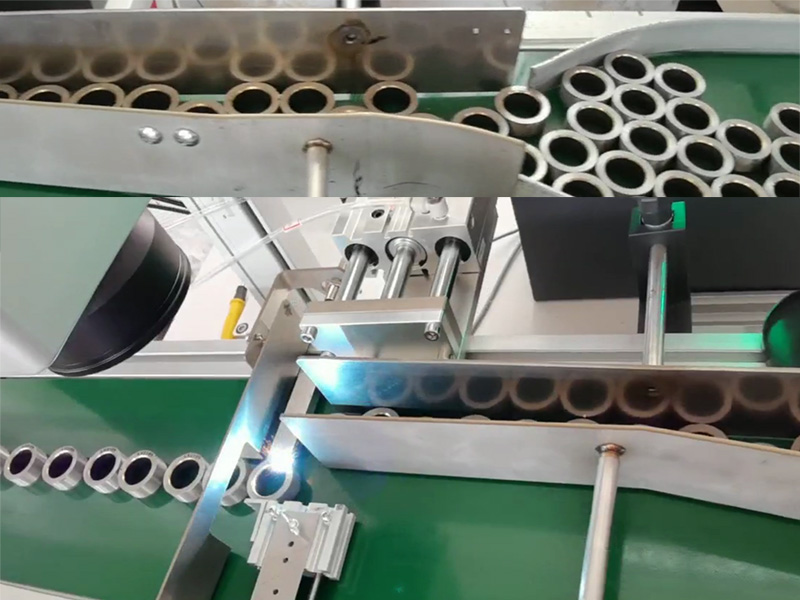

Jewelry Laser welding machine Display

Specification of Mini Laser Welding Machine

|

Model

|

MZ-LW60

|

|

Output Power

|

60W / Peak power:100W ND:YAG

|

|

Laser Wavelength

|

1064nm

|

|

Laser welding pool

|

0.1mm

|

|

Single pulse energy

|

60J-110J

|

|

Laser Pulse frequency

|

<20Hz

|

|

Laser Pulse Widtch

|

0.1—20ms

|

|

Focus spot

|

0.1-2.0mm

|

|

Red Light spot

|

0.2-3.0mm

|

|

Power Max

|

4KW

|

|

Power Supply

|

220VSingle Phase/50Hz/20A

|

|

Observation of welding area

|

Both HD CCD Camera and Microscope

|

|

Dimension

|

920X560X1220mm

|

Features of Mini laser welding machine for jewelry

Advantages

1 The ergonomic design of the whole machine is more suitable for the jewellery industry, with fine products, beautiful appearance, stable performance, and suitable for long-term continuous work;

2 The operation software can select Chinese or English interface, and select the corresponding laser welding processing parameters for different processing positions. The cursor is moved to the corresponding parameter position by the selection button, and the size of the parameter is adjusted by the adjustment button;

3 Based on the 10X microscope observation system, the first use of high-definition CCD observation system to ensure that the spot welding effect is beautiful;

4 Assembled with a liquid crystal shutter with independent intellectual property rights, the shutter will work with the laser light and off light to achieve laser welding jewelry shielding flash when the flash, the light is turned off when the laser is off, protect the eyes of the operator is not affected by the laser Blinking and feeling uncomfortable;

5 Argon gas protection device can be installed. This function can effectively protect the welding position in the welding process is always protected by argon, always maintain the metal color, ensure the welding quality;

6 With 24-hour continuous work capability, the whole machine has stable working performance.

Original Source: Whatsapp:+8614753226012