Today, we will show you how to black marking on anodized aluminum surface with our mopa fiber lasre marking machine 30 watts. Some buyers of fiber laser marking machine told me they can't get black engraving on aluminum surface with their fiber laser marking machine 20 watts or 30 watts. Only can do a little deep engraving on aluminum materials, but can't get black marking on it. That's why we introduce you our special fiber laser marking machine named 30 watts Mopa fiber laser marking machine with JPT Mopa fiber laser source M7 model.

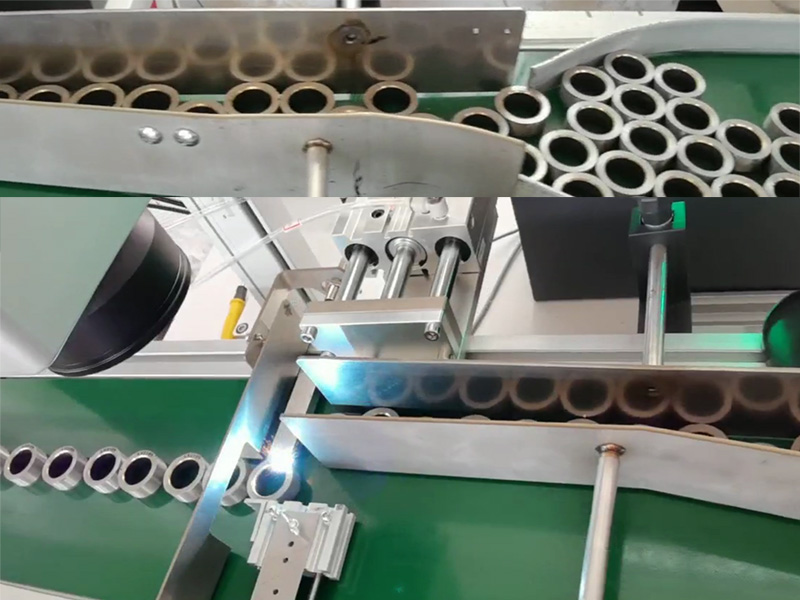

The below is JPT Mopa fiber laser source M7 series, its pulse width adjusting range is 1-500ns, Frequency adjusting range is 1-4000KHz.

The second type fiber laser marking machine is named mopa fiber laser marking machine, it is mainly used for stainless steel color engraving and some senstive plastic that common fiber laser can't laser mark well, and also anodized alumium black laser engraving and marking. For anodized aluminum black marking, usually set short pulse width such as 2/4/6/10 ns, all no problem to get black marking on anodized aluminum surface, but it also should work with suitable frequency to work with pulse width. For anodized aluminum black laser marking, it needs high laser frequency, usually adjust from 200-600KHz, it depends on the thickness of anodized layer, usually 10-20um thickness is more easy to get black marking on anodized aluminum. The thin layer need weak laser power will be ok, if thicker layer, it need higher laser power to get it burn black. If using 20 watts Mopa fiber laser, its laser power setting usually set from 40-80% according to the lens you used. If using 30 watts fiber laser, usually set laser power from 30-60% will be ok.

Below is black marking on anodized aluminum by JPT mopa fiber laser marking machine 30 watts.

Below is the black marking on anodized aluminum surface by JPT mopa fiber laser 30 watts