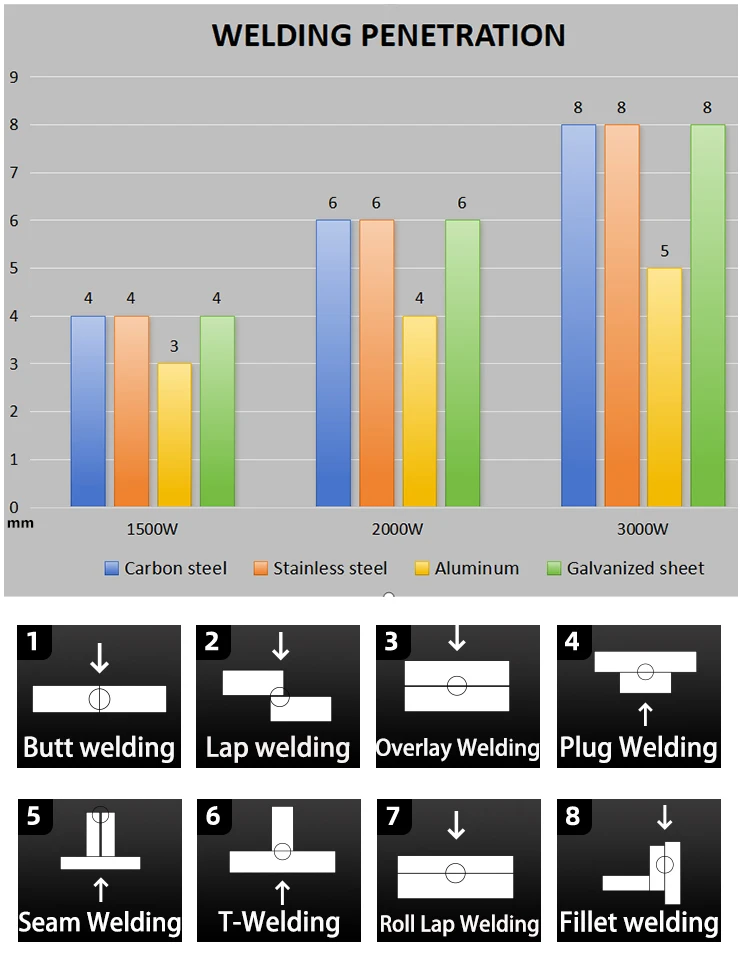

How thick will a laser welder weld?

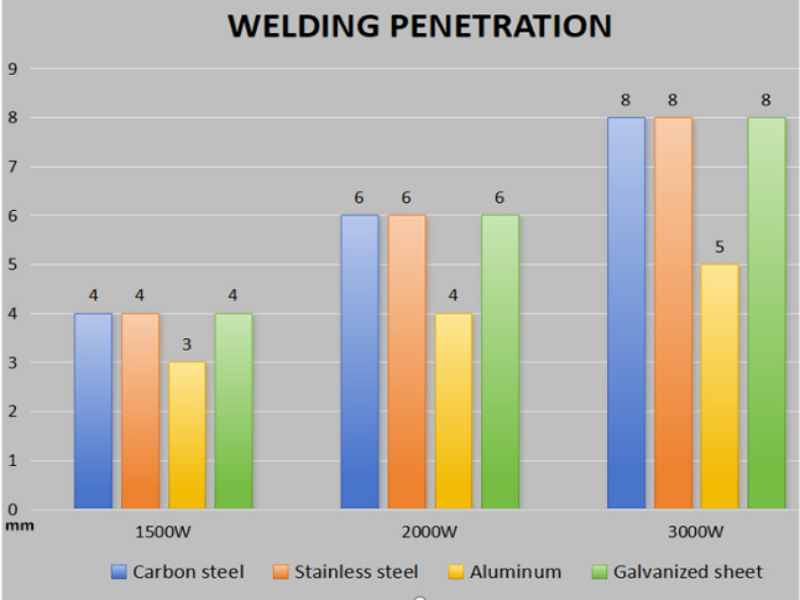

Handheld laser welders can weld a variety of metals and their alloys, like carbon steel, mold steel, alloy steel, stainless steel, titanium, copper, aluminum, and more. They can also handle laser welding requirements between different types of metal materials. The equipment is small in size and easy to use with flexibility. It's mainly designed for welding thin-walled materials and precise parts to produce high-quality welds. No grinding is needed which results in stronger and more efficient outdoor-capable welding that can be done at long distances or any angle or shape with ease. The maintenance and operating costs are low without the need for consumables.

In conclusion, the advent of handheld laser welders marks a significant advancement in the field of metal processing. Their versatility, efficiency, and precision have revolutionized the welding industry, offering solutions to challenges posed by traditional welding methods. With the ability to weld various metals and alloys, these machines have become indispensable tools in modern manufacturing processes.

As technology continues to evolve, handheld laser welders are poised to play an even greater role in meeting the demands of diverse applications. With ongoing developments in laser power, materials science, and welding techniques, the capabilities of these machines are expected to expand further, enabling the welding of thicker materials and addressing new challenges in metal processing.