Fiber Laser Settings Ezcad for Aluminum Brass Plastic

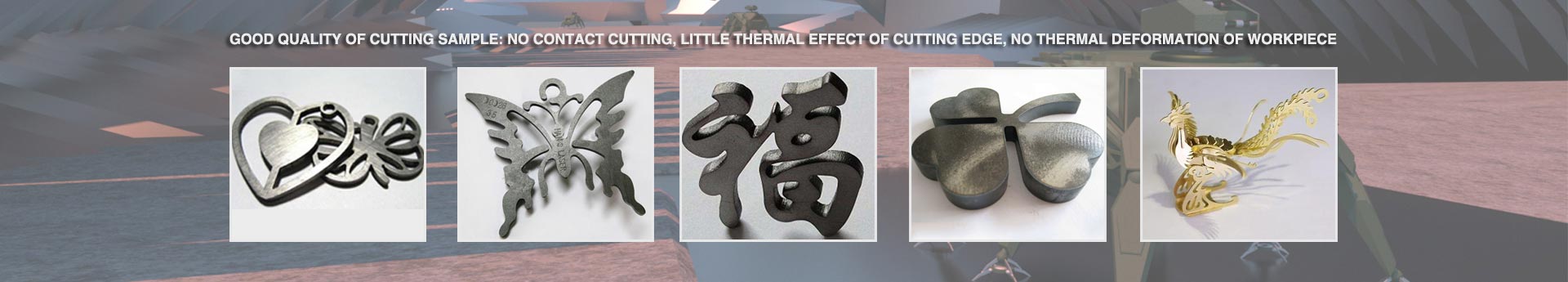

Today fiber laser marking machine is very hot sale in the laser machine market, becuase it can work on all metals such as iron,aluminum,brass,copper,stainless steel, and metal alloy... and also no problem to work on plastic materials and other most of no-metal materials. Very widley used for home personal use and industrial use. But many buyers don't know how to do right ezcad settings for each kind of materials, which will cause some trouble during use. Today we will share you some fiber laser settings ezcad, such as fiber laser settings for brass and aluminum, and fiber laser settings ezcad for plastic.

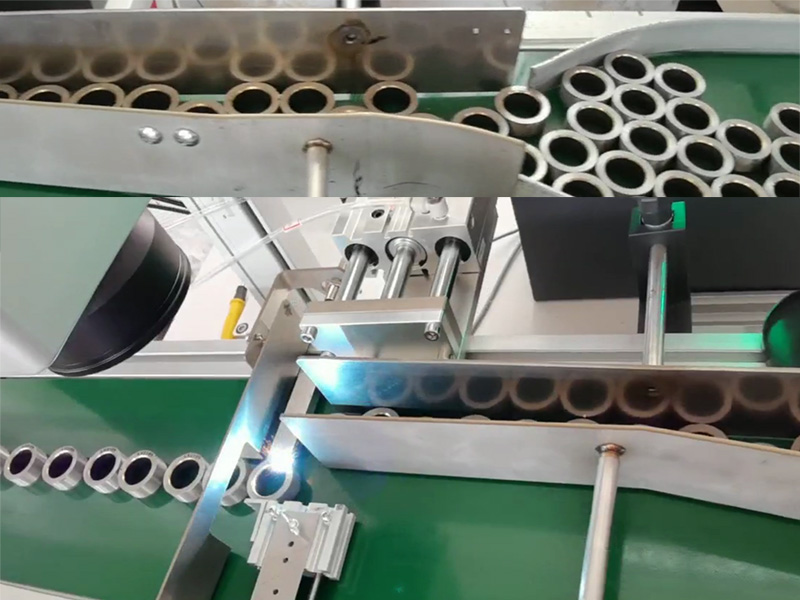

The below is the hot sale fiber laser marking machine

For ezcad setting, it is already setted before shipping. when customers received our machine, usually just set Speed(S):0-4000mm/s, Laser power(L):1%-100% Frequency(F):20Khz-80Khz. Laser Pen setting. and also need to do ezcad hatching setting. such as hatch type, line distance:0.01-0.1mm.

For metal marking such as aluminum, brass,stainless steel, we can set: S:1500,L:50%, Frequency:25KHz. Hatching line distance: 0.05mm. It will mark very light, not too deep. If you want to deeper engraving, you can slow down speed and increase laser power and set several marking loops. You can set: S:800, L:95%, Frequency:20HKz. Marking loops: 10. It will go to engrave 10 times then stop, then you will get deeper engraving effect. For metal engraving,it is very easy to do ezcad setting. While for plastic laser printing, it will be not easy like metals. Because there are too many kinds of plastic components. But fiber laser settings for plastic, we should try to set low laser power, fast speed, and bigger hatching lines distance to avoid the plastic too much burned by fiber laser. First, we can set speed:1500-3000, laser power:20-35%, hatching line distance: 0.05mm. after setting then go to mark. if result is good, then this ezcad parameters setting will be ok for you. If invisible, you can increase laser power to try second time, if already can see the laser marking on it. you can increase laser power again. If still not good, or light burn, you can slow down speed, then adjust like this to get the best result. Of course, there are also many kinds of plastic that not good for fiber laser printing.

If you still have difficuty for fiber laser settings ezcad, then just feel free to contact us whatsapp:+8614753226012 to ask for help.