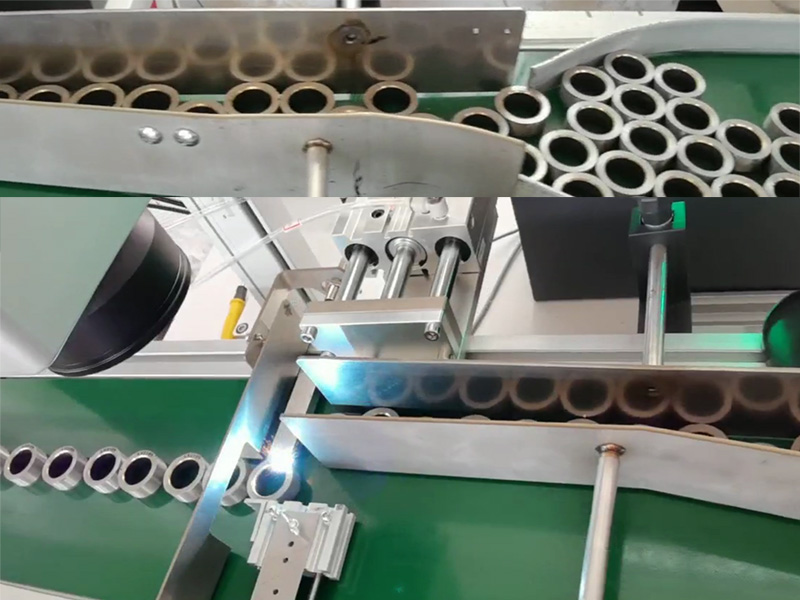

This fiber laser cutting machine is a new metal cutting machinery, it can cut thin metal sheet with high speed,and the cutting edge quality is very good, usually no need to do after processing to the cutting edge. it is mainly used for metal sheet,stainless steel sheet,and aluminum,brass,and other metal materials....

Product Descriptions

Metal sheet fiber laser cutting machine with cost-effective price

-

Advantages of fiber laser metal cutting machine

All laser cutting processes have their own inherent advantages and disadvantages, but it appears that the benefits of fiber laser cutting machines far outweigh that of any of the other processes. It’s one of the newest forms of laser cutting, as it’s only picked up traction in the last couple decades or so. However, the benefits that fiber laser cutting machines provide, which we will discuss below, have been quickly realized by metal fabricators all over the country. Fiber laser cutting machines can easily and seamlessly adapt between industries for a huge range of applications. Continue reading to learn more about the other benefits of these powerful machines.

-

Applicable industry and material:

Application Materials: Fiber Laser Cutting Equipment is suitable for metal cutting like Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc.

Application Industries:

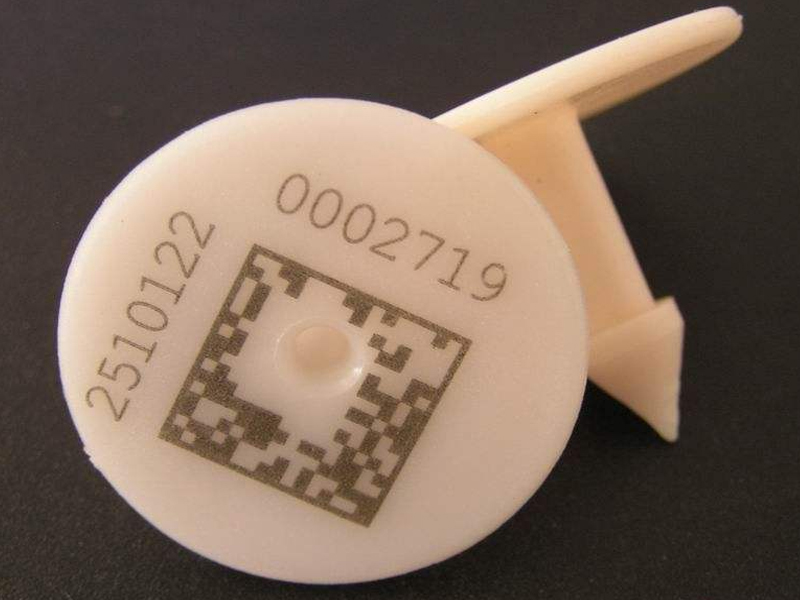

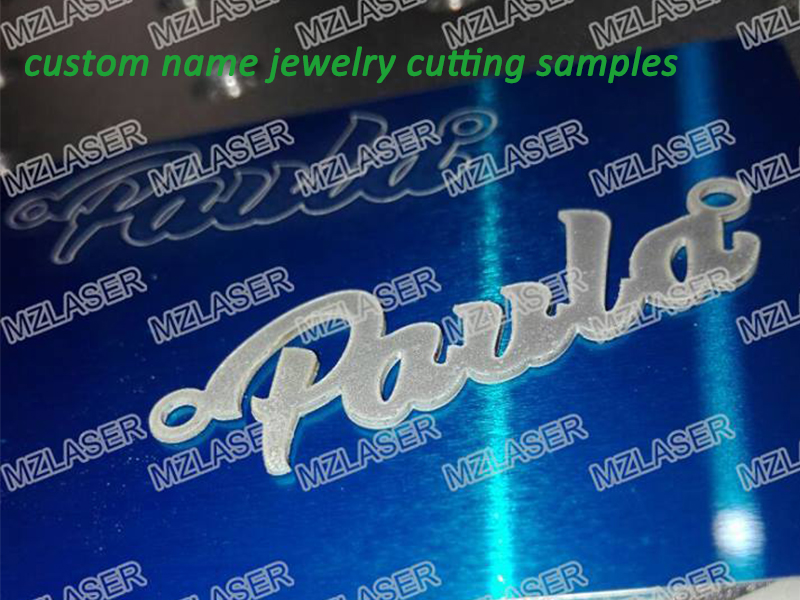

Fiber Laser Cutting Machines are widely used in manufacture Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

-

Specifications of fiber laser cutting machine :

|

1530 Model Fiber Laser Cutting Machine

|

|

Model

|

MZ-FC1000M

|

Servo Motor And Driver

|

Yaskawa From Japan

|

|

Laser Power

|

1000w

|

Reducer

|

Germany Neugart

|

|

Transmission

|

Taiwan Yyc Rach And Pinion

|

Water Chiller

|

Doluyo 1p

|

|

Laser Source

|

Ipg Laser

|

Control System

|

Cypcut From Shanghai, China

|

|

Cutting Head

|

Raytools

|

Computer

|

Advantech Industry Computer

|

|

Lathe Bed

|

MZLASER

|

Power Requirement

|

3 Phase Ac 380v 50hz

|

|

Guide Rail

|

Pmi From Japan

|

Gross Weight

|

3.05mts

|

|

Terminal Row

|

Germany Weidmuller

|

Relay

|

Germany Siemens

|

|

Solenoid Value

|

Taiwan Airtac

|

Proportional Value

|

Japanese Smc

|

-

Fiber laser cutting machine picture

-

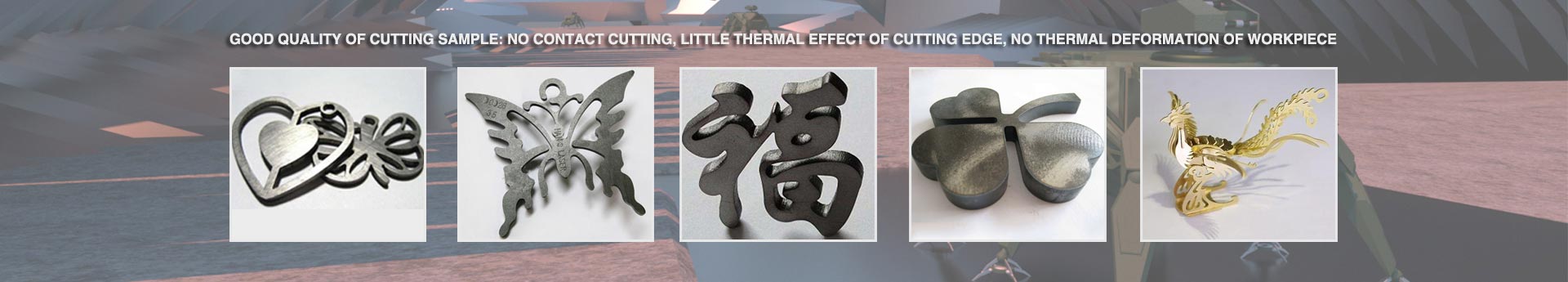

Metal cutting samples by fiber laser cutting machine

-

Installation,training and after sales service

1.Installation

After the machine reach the buyer’s factory, our engineers from the seller are responsible for machine installation and commissioning by using the special tools under the help of the buyer. And then start training the workers.The buyer will be responsible for the round-trip air tickets,accommodation,safe in buyer’s country.

2.Training

The common protection knowledge of laser safety

The basic principle of laser module and the structure of laser cutting machine

The operation skills of fiber laser cutting machine

Equipment operation and the application notice

Skills of equipment daily maintenance,laser module adjustment and spare parts replacement.

Training time is about 5 to 7 days.