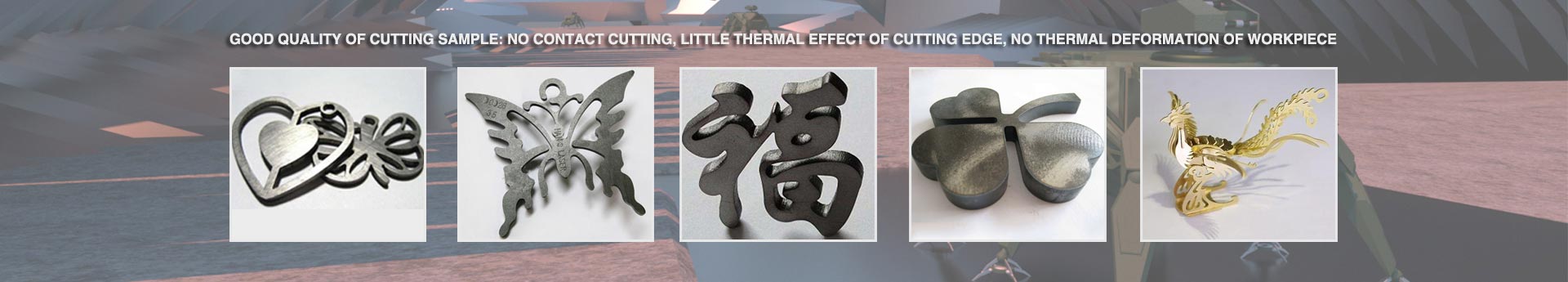

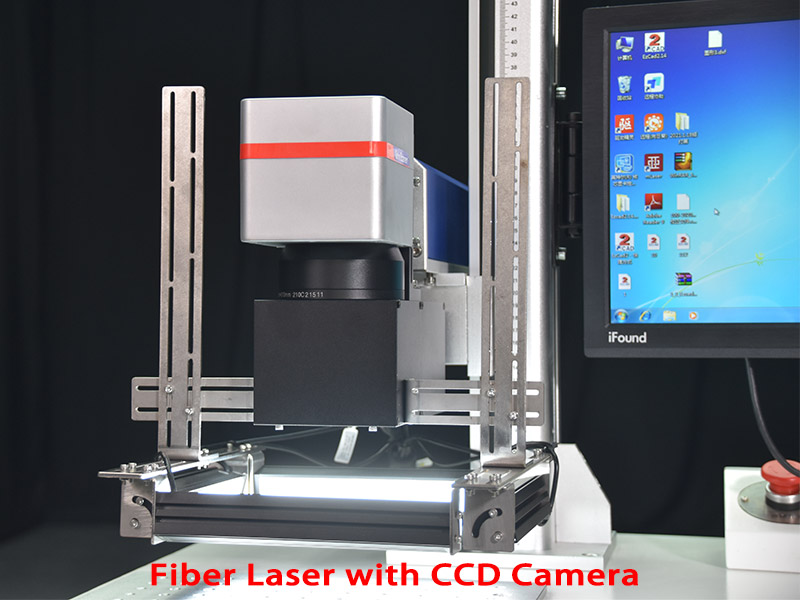

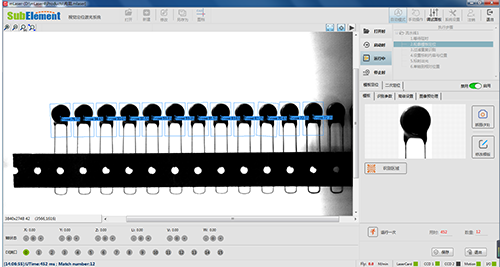

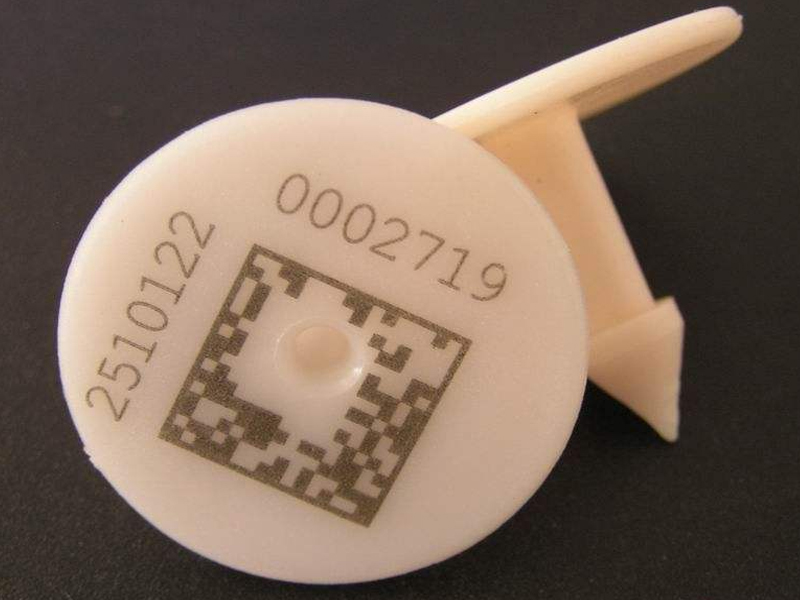

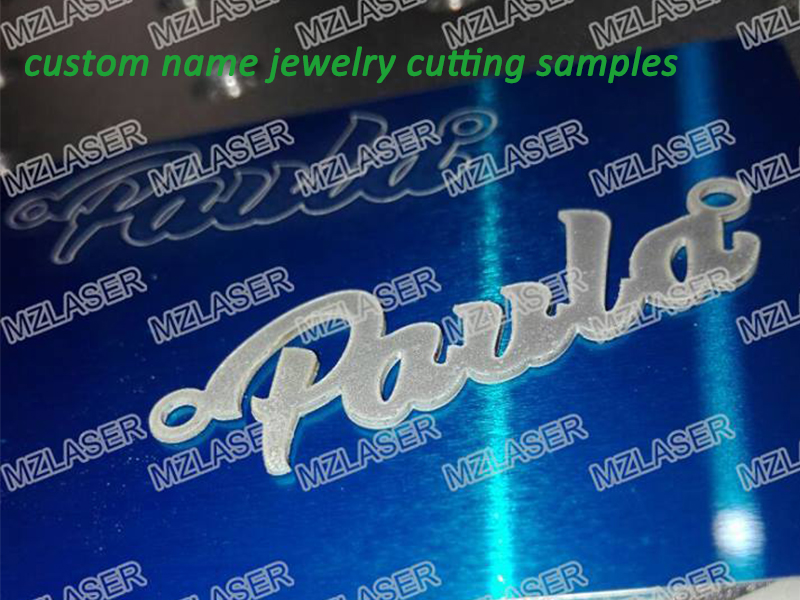

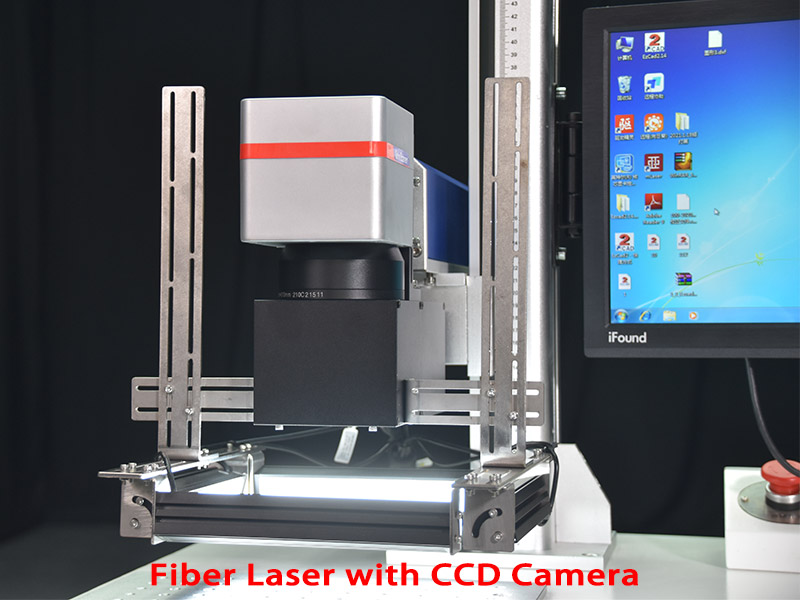

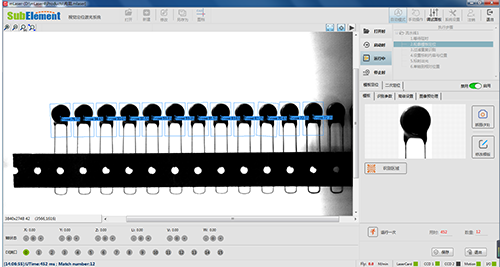

It is not easy to do high precision positioning for small parts oe letters, especially by hands,so We M&Zlaser developped a automatic visual positioning fiber laser marking machine with ccd camera. This fiber laser marking machine with ccd camera scanning control system is equipped a 5 megapixel coaxial CCD camera control system with high dpi and precision, it can realize automatic visual positioning,and the positioning speed is fast and precision is about 0.01mm. This industrial laser marking machine is especially suitable for marking on ultra high-precision valuable parts which is not easy to be positioned by hand, such as: electronic components, IC chips, circuit boards, resistors, small capacitors, metal buttons, pens, etc., more suitable for marking on the parts which is not possible for positioning by hand....

Product Descriptions

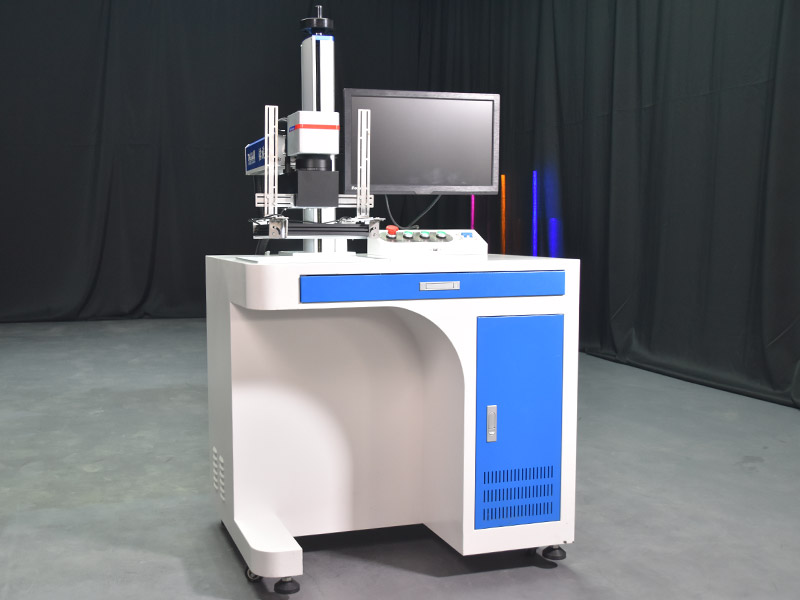

Auto Visual Identifying & Positioning CCD Fiber Laser Marking Machine 20W 30W 50W Engraving Machine with CCD Camera for IC Chips and Power Supply Shells

1. Feature:

Automatic visual positioning laser marking machine with CCD camera:

When traditional laser marking machines need to realize automated production, they have high requirements for mechanical precision. The production of a complex automated matching line can only be applied to one or a few products.

For new products, a new production line needs to be made, which not only has a long cycle time, but also is not conducive to the cost management of the factory.

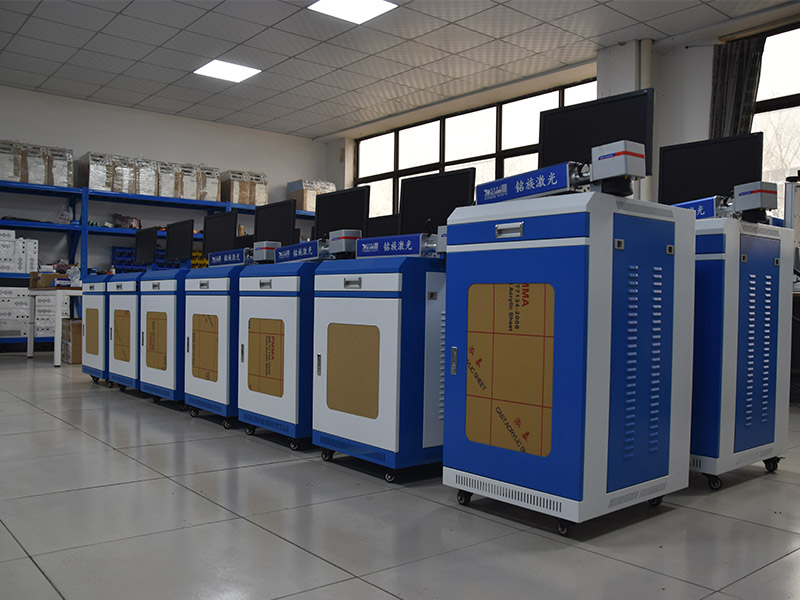

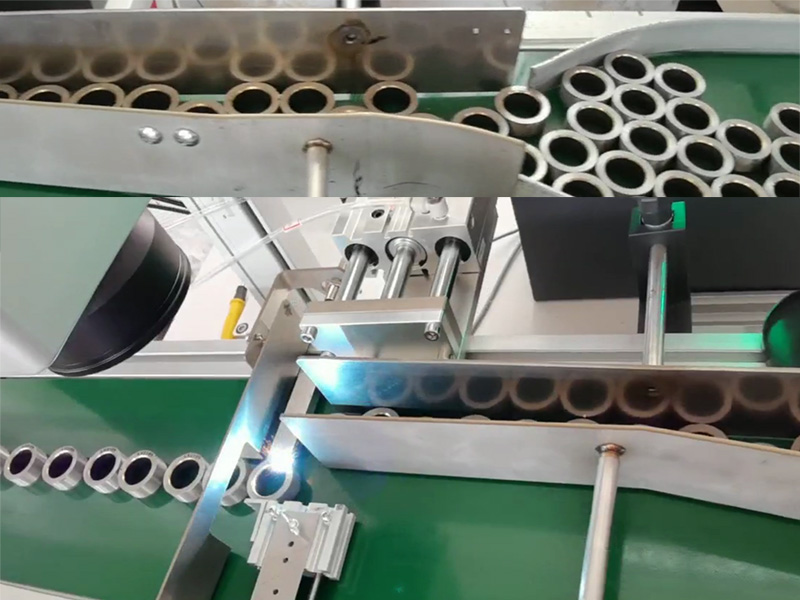

In response to the above phenomenon,M&ZLASER has developed a visual positioning laser marking system to achieve rapid positioning, marking multiple products at a time, or automatic assembly line feeding, and then performing visual positioning marking after rough positioning, saving labor and improving production Efficiency, easy to realize an automated production line.

2. Principle of visual marking machine:

Based on the basis of traditional marking machines, a high-precision CCD camera is used to capture the current position of the product, and the position information of one or more products collected in real time is transmitted to the marking card through the computer in order to achieve precise marking . As long as the laser marking scanning galvanometer is within the processing range, accurate marking can be achieved.

3. Case:

Suitable for manufacturing industry: It is mainly used for products with heavy labor and difficult feeding positioning, such as: mobile phone shells, U disks, IC chips, power supply shells, hardware accessories, plastic product patterns, models, etc.

4. Techncial Parameters

|

No.

|

Technical Item

|

Technical Parameters

|

|

No.

|

Technical Item

|

Technical Parameters

|

|

1

|

Power Rate

|

20/30/50/60/100W

|

|

7

|

Marking Line Speed

|

< 7000mm/s

|

|

2

|

Wavelength

|

1060-1064nm

|

|

8

|

Laser Lifetime

|

>100000hours

|

|

3

|

Beam Quality

|

M2 less than 1.5

|

|

9

|

Cooling Method

|

Air Cooling

|

|

4

|

Min. Character

|

0.05mm

|

|

10

|

Machine Power

|

Less than 600W

|

|

5

|

Min. Line Width

|

0.01mm

|

|

11

|

Power Supply

|

220V 50Hz/ 110V 60Hz

|

|

6

|

Repeatability

|

±0.001mm

|

|

12

|

Package Weight

|

130Kgs

|

5.Main Components

5.1 Laser Source: Raycus/ MAX/ IPG

5.2 Galvanometer Scanner: NYYG/ SINO-GALVO